How to Choose Shipping Box Size, Shape and Strength

Question:

I had a shipment that was inspected with QC before sending to my forwarder.

Box dimensions was 504550 cm.

Once it arrived to the forwarder warehouse, my forwarder sent me updated box dimensions

of 514751 and charged me with increased volume on my final invoice.

How can I prevent it from happening again in my next shipment?

How is this possible if I did a QC inspection before cargo was sent out from the factory?

Answer:

Whether you're looking to ship something smaller than your hand or so big it needs to be

moved in a truck, picking the right box is important. With various shapes, sizes and

strengths, it can be challenging to know where to begin. This guide will help you choose the

right shipping box to fit your business needs.

Typical standard shipping boxes are made of corrugated cardboard. You can choose from an

assortment of shapes and box strengths. Depending on the size and weight of your product,

you may need a more durable box.

Box Strengths

The two most commonly used box strengths for shipping are:

• 32 ECT: This type of box can stand up to a 32-pounds per square inch vertical compression

and is common when stacking lighter weight shipments.

• 200#: For somewhat heavy-duty shipping, 200# boxes are popular options, and generally

support a bursting strength of about 50 percent higher than 32 ECT boxes.

When boxes are pelletized, they are likely to receive much less of the rough treatment that

causes box walls to burst, but their stacking strength is still very important.

According to Proboxx’s experience, many shippers of palletised freight prefer to choose

boxes based on ECT ratings, because this more directly describes stacking strength.

Shipping Boxes Are an Important Part of Product Delivery

With the right boxes ready to go, your business can successfully meet its shipping and

packaging needs, while providing safe and secure delivery. Taking the time to understand

shipping box sizes and shapes will help you reach the best result for your customers—and

that's an ideal outcome for any business.

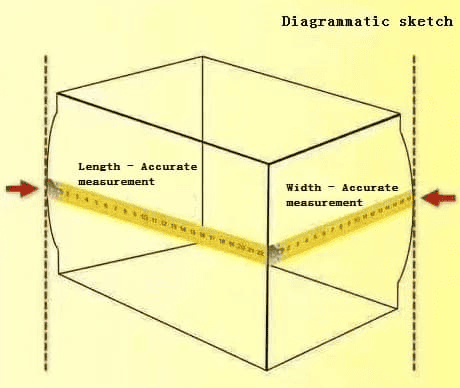

How are the dimensions of a corrugated box normally expressed?

Box dimensions are given in this order: Length (the longest side of the opening) x Width (the

shorter side of the opening) x Depth (the dimension perpendicular to the opening. Get more

guidance on types of box by size.

What is a standard size shipping box?

There is no exact requirement for the standard size shipping box. Looking at your own

business and personal packages, you’re likely to see boxes with a wide range of shapes and

sizes. You can find a box to meet nearly any shipping box need.

How do I know what size box I need?

Measure your product to ensure you don’t pick a box that’s too small or too big, taking into

account added space for padding. You may want to test multiple box sizes to find the right fit

for your product.

Also, be mindful of Amazon TOS and FBA storage fees so you don't pay extra storage fees for

no reason. This can gather to thousands of USD which can be avoid by knowing Amazon

regulations and storage fees.

UPDATE: TEAM LIFT/HEAVY PACKAGE. If your package is above 15KG/33LBS then you need to add 5 labels on your cartons box.

My box dimensions were increased from the original dimensions even though I performed a QC inspection?

During transportation, cargo will be deformed and the volume will increase. The original

rectangular box may become as below. The side of the box will bulge out.

At the same time, loading warehouse is going to count the bulge as the chargeable volume.

Hence, the chargeable volume will be increased based on the final volume that was

calculated at your forwarder yard.

As a side note, a good and reliable forwarder should send your reference pictures to ensure

he took the right measure of the boxes.

Do not rely just on the forwarder for final measurements. Demand for pictures, videos or

any other reference to ensure measurements were done correctly.