How Amazon Sellers Turn Lead Time, Demand Forecasting, and Inventory Allocation into a Controlled System

Article by Dan Badler

Many Amazon sellers are profitable on paper and exhausted in reality.

They sell well, scale SKUs, and invest heavily in growth. Yet inventory is always late, too early, or in the wrong place. Cash is locked in products that move too slowly. Stockouts happen right before peak periods. Expedited shipments become routine. Management attention is consumed by operational noise instead of strategy.

Most sellers assume this is normal. They blame Amazon, seasonality, suppliers, or logistics partners. Many believe inventory pressure is simply the price of growth.

It is not.

in almost every case, the root cause is the same. Inventory is being managed reactively instead of as a controlled system. Decisions are made too late, without structure, and without alignment between demand forecasting, lead time, and inventory allocation.

This article explains why Amazon sellers keep chasing inventory and how mature operators replace firefighting with predictability, control, and operational calm.

Inventory Is a Financial Problem, not a Logistics Problem

Inventory is often discussed in units, cartons, or pallets. Mature operators discuss it in terms of cash, risk, and decision timing.

Every inventory mistake has a direct financial impact.

When a product is out of stock, the damage extends beyond missed sales. Rankings drop. Organic momentum is lost. Advertising costs increase when inventory returns. Recovery is expensive and slow.

When inventory is excessive, the damage is quieter but just as real. Cash is locked and unavailable for growth. Storage fees accumulate. Margins erode through forced discounts. The risk of obsolescence increases.

Expedited shipping feels like a solution, but it is actually a margin transfer. Seller’s trade long-term profitability for short-term relief.

Inventory is not a warehouse problem. It is a capital allocation problem. Capital allocation problems cannot be solved by shipping faster alone.

Demand Forecasting Without Lead Time Is Guesswork

Many sellers forecast demand. Far fewer forecast demand in relation to the actual lead time.

Forecasting without understanding lead time variability creates false confidence. Orders appear to be placed on time, yet arrive too late. Safety stock grows to compensate for uncertainty. Larger orders feel safer, but increase financial exposure.

The issue is not forecast accuracy by itself. The issue is that forecasts are disconnected from how long decisions and execution actually take.

Until lead time is measured, broken down, and managed as a system, demand forecasting remains fragile. It becomes an educated guess rather than a reliable planning tool.

Lead Time Is Not Shipping Time

One of the most damaging misconceptions in Amazon operations is equating lead time with transit time.

Lead time does not begin when the cargo leaves the factory. It begins when a decision is made.

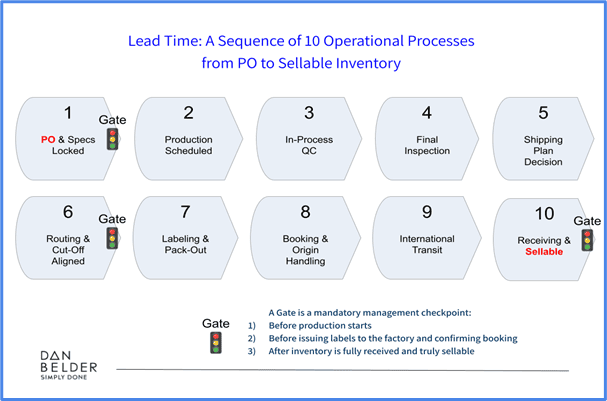

A controlled lead time includes the full sequence of decisions and execution steps, including:

- Purchase order finalisation and specification lock

- Production planning and factory follow up

- In process quality control

- Final inspection and defined rework window

- Shipping plan decisions such as FBA, AWD, third party logistics, or split

- Routing, sailing schedule, and cut off alignment

- Labeling and final pack out

- Booking and origin handling

- International transit and customs clearance

- Receiving and sellable availability

Most delays occur before cargo ever moves. This is where control is either established or lost.

Sellers who focus only on shipping time ignore the majority of the system that determines success or failure.

Gates: Why Mature Operators Stop the Process on Purpose

In immature operations, the process always moves forward. Progress is confused with movement.

In mature operations, the process is deliberately stopped.

A Gate is a mandatory decision checkpoint. It answers one question only. Are we allowed to move forward, yes or no?

Key Gates in a controlled system include:

The Purchase Order Gate. Production does not begin until specifications, packaging, and timelines are fully locked.

Any change after this point will result in guaranteed cost and time deviations.

The Ready for Labeling Gate. Labels and bookings are not issued until final inspection is complete, rework is closed, and the shipping plan decision is final. Labels issued earlier almost always lead to relabeling, delays, or forced routing decisions.

The Sellable Gate. Inventory is counted only when it is truly available for sale. Arrival does not equal sellable. Planning based on arrival creates false availability and downstream stockouts.

Gates prevent expensive mistakes disguised as progress. They slow the process in order to speed outcomes.

Inventory Allocation Is a Business Decision

Choosing between FBA, Amazon Warehousing and Distribution, third party logistics, or a split strategy is not a logistics preference. It is a business decision about control, risk, and capital

.

exposure

FBA offers simplicity and scale, but limits intervention and flexibility.

AWD provides buffering within Amazon’s ecosystem, but requires disciplined consumption planning.

Third-party logistics offers flexibility, rework capability, and control over decision-making, but it requires active management.

Split strategies reduce dependency on a single scenario and allow sellers to balance availability and risk.

Mature sellers allocate inventory based on where failure would be most expensive, not where handling is easiest.

Buffers Are Tools, Not Extra Inventory

A buffer is not inventory kept “just in case.”

A buffer is inventory that is intentionally placed, assigned a specific purpose, and released only under predefined conditions.

A proper buffer answers three questions before inventory is ordered:

Where does the buffer sit

What risk is it designed to absorb

Under what conditions is it released

Without clear rules, buffers become hidden overstock. With rules in place, buffers absorb variability without managerial panic.

Firefighting Is a Management Choice

Expedited shipments, last minute reallocations, and emergency decisions are not inevitable. They are symptoms of systems without structure.

Firefighting occurs when there are no Gates, no buffer rules, no inventory allocation logic, and no shared operational language.

It consumes margin, leadership attention, and organisational energy. It also creates a false sense of urgency that masks root causes.

Operational calm is not accidental. It is designed.

What Differentiates Sellers Who Scale Cleanly

High-performing Amazon sellers do not eliminate variability. They design it.

They replace heroic interventions with systems. Decisions are made earlier rather than faster. Fewer surprises occur because fewer decisions are postponed.

They manage lead time as a measurable system. They align forecasting with reality. They allocate inventory intentionally.

The result is not perfection. The result is predictability, financial control, and lower cognitive load for leadership.

Conclusion: Stop Managing Inventory. Start Managing Decisions

Inventory is not the problem. Amazon is not the problem. Shipping is not the problem.

Unstructured decision-making is the problem.

Sellers who master lead time, align demand forecasting, allocate inventory intentionally, and enforce operational Gates stop chasing inventory.

They build businesses that scale without burning cash, margins, or management attention.

Inventory does not need to be controlled perfectly. It needs to be controlled intentionally.

***

About Dan:

Dan Belder is an operations and supply chain expert with over 35 years of executive and advisory experience.

He works with Amazon sellers, from established six-figure brands to scaled operations, to build disciplined and reliable operating models.

Dan partners closely with founders and leadership teams on lead-time control, demand-forecast alignment, and inventory allocation decisions.

His work combines strategic thinking with hands-on execution to reduce inventory risk and operational noise.

He helps sellers improve profitability, cash flow stability, and management focus as they grow.

Dan previously served as Vice President at UPS Israel and as leader of Deloitte Israel’s Operational Excellence Consulting Practice.

Proboxx clients receive a 15% discount on strategic and tactical operational consulting.